Zvigadzirwa

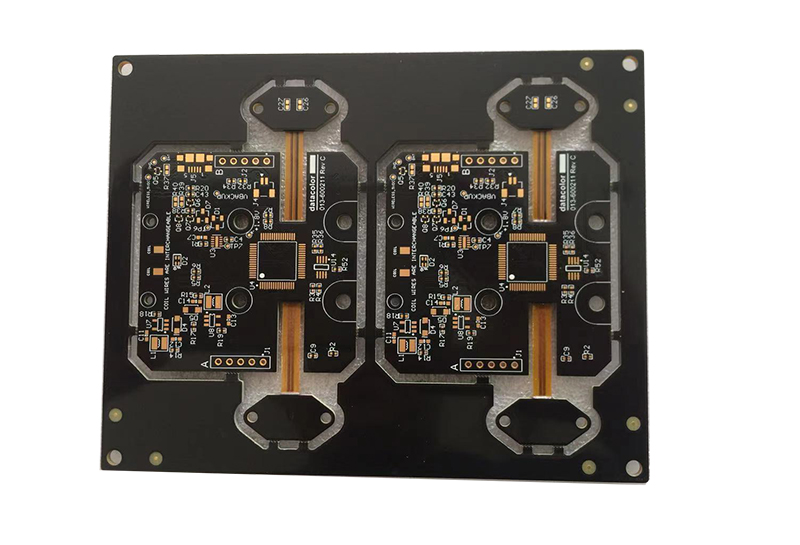

Industril Sensor 4 Layer Rigid & Flex PCB ine 2z copper

| Materers | 4 maratari akaomarara + 2 liders flex |

| Bhodhi ukobvu | 1.60mm + 0.2mm |

| Zvinhu | Fr4 TG150 + Polymide |

| Copper Bickness | 1 oz (35um) |

| Kumusoro Kupedzisa | Enig u gobvu 1um; Bickness 3um |

| Min gomba (mm) | 0.21mm |

| Min mutsara upamhi (mm) | 0.15mm |

| Min Line Space (MM) | 0.15mm |

| Sengesa Mask | Girinhi |

| LEGEND COUL | Chena |

| Mechancal kugadzirisa | V-Kurova, CNC Kugaya (Kuenderera) |

| Kurongedza | Anti-static bag |

| E-bvunzo | Kubhururuka probe kana chidimbu |

| Kugamuchirwa Standard | IPC-A-600H Kirasi 2 |

| Application | Zvemagetsi emagetsi |

Nhanganyaya

Rigid & Flex PCBS yakasanganiswa nemabhodhi akaomeswa kugadzira iyi hybrid chigadzirwa. Mamwe matombo echigadzirwa anogadzira anosanganisira dunhu rinoshanduka rinomhanya mumabhodhi akaomarara, kufanana

chiyero chakajairika chedunhu dunhu.

Mugadziri webhodhi anowedzera akabatanidzwa kuburikidza nemakomba (pths) iyo inobatanidza nzvimbo dzakaomarara uye dzinochinja-chinja sechikamu cheichi chiitiko. Iyi PCB yaive yakakurumbira nekuda kwehungwaru hwayo, kunyatsoziva, uye kushanduka.

Tigid-flex inochinjika ichirerutsa maitiro emagetsi nekubvisa tambo dzinochinjika, kubatana, uye kushandisa kweumwe neumwe. Rudzi rwekushomeka & dzinotenderera

Mainjiniya anogona kutarisira zvakanyanya kuwanda uye kuita kwemagetsi kutenda kune yakaomeswa-flex flex yePCB's yemukati magetsi uye michina yekubatanidza.

Zvinhu

Substrate zvinhu

Iyo inonyanya kuzivikanwa yakaoma-ex chinhu chakarukwa fiberglass. Iyo gobvu yeiyo ipoxy resin machira ichi fiberglass.

Zvakangodaro, epoxy-isingakwanisi ferglass haina chokwadi. Izvo hazvigone kumira zvisina kunaka uye zvinovhundutswa.

Polyimide

Izvi zvinyorwa zvinosarudzwa pakuchinjika kwayo. Iyo yakasimba uye inogona kutsungirira mabwe uye mafambiro.

Polyimide anogona zvakare kutsungirira kupisa. Izvi zvinoita kuti zvive zvakanaka kune zvinoshandiswa nekudziya tembiricha.

Polyester (pet)

Pet inofarirwa nehunhu hwayo hwemagetsi uye kuchinjika. Zvinoramba zvemakemikari uye kusimba. Izvo zvingangove zvinoshandirwa mumamiriro ezvinhu ehutsinye maindasitiri.

Kushandisa substrate yakakodzera simba raunoda simba uye hupenyu hurefu. Izvo zvinofunga zvinhu sekushisa kudzikisira uye kudzikama kudzikama uku uchisarudza substrate.

Polyimide emainesives

Iyo tembiricha yekudziya yeiyi inonamatira inoita kuti ive yakakodzera basa. Inogona kumira 500 ° c. Yayo yakakwira kupisa kupokana inoita kuti ive yakakodzera kune dzakasiyana siyana dzekushandisa.

Polyester aomhan'ara

Aya mainhuwa anowedzera mari inodhura kupfuura polyimide kuomerera.

Ivo vakanaka kuti vagadzikane nekukasira kuputika chiratidzo chechiratidzo.

Ukama hwavo hwisina kusimba. Polyester Mahonyeti haana zvakare kupisa anopesana. Ivo vakagadziridzwa munguva pfupi yapfuura. Izvi zvinovapa ivo nekupisa kupisa. Uku kuchinja kwacho kunosimudzirawo kuomerera. Izvi zvinovaita kuti vakachengeteka mune multilayer PCB musangano.

Acrylic ainesives

Aya mainhesives akakwirira. Ivo vane yakanakisa yekudzivirira yekukanganisa kurwisa kuora uye makemikari. Ivo vari nyore kushandisa uye kushayikwa. Zvakasanganiswa nekuwanika kwavo, ivo vanozivikanwa pakati pevamwari. Vagadziri.

Epoxies

Izvi zvinogona kunge zvichinyanya kushandiswa zvakanyanya mukugadzira-flex wedunhu rekugadzira. Ivo vanogona zvakare kutsungirira kuparadzira uye kupisa kwakanyanya uye kwakaderera.

Ivo zvakare vanochinjika zvakanyanya uye zvakanyanyisa kugadzikana. Iyo ine polyester madiki mairi iyo inoita kuti ive inoshanduka.

Stack-up

Iyo stack-kumusoro kweiyo yakaoma-ex PCB ndeimwe yezvikamu zvakawanda panguva

rigid-ex PCB fantation uye zvakanyanyisa kuomesa kupfuura chiyero

Mabhodhi akaomarara, ngatitarisei tarisiro yezvinhu zvina zveReigid-ex PCB se pazasi:

Wepamusoro Solder Mask

Pamusoro

Dielectric 1

Signal layer 1

Dielectric 3

Signal layer 2

Dielectric 2

Zasi layer

Pasi soldermask

PCB kugona

| Rigid Board Kugona | |

| Nhamba yezvikamu: | 1-42 matare |

| Chinyorwa: | Fr4 \ High TG Fr4 \ Tungamira Mahara Zvinyorwa \ CEM1 \ Cem3 \ Aluminium \ Simbi Core \ PTFE \ Roger \ Roger |

| Out layer cu ukobvu: | 1-6oz |

| Mukati layer cu gobvuess: | 1-4oz |

| Maximum yekugadzirisa nzvimbo: | 610 * 1100mm |

| Minimum Bhodhi Bickness: | 2 Layers 0.3mm (12mil) 4 Layers 0.4mm (16mil)6 Layers 0.8mm (32mil) 8 Layers 1.0mm (40mil) 10 Layers 1.1mm (44mil) 12 Lates 1.3mm (52mil) 14 Layers 1.5mm (59mil) 16 nzira 1.6mm (63mil) |

| Minimum Yakakura: | 0.076mm (3mil) |

| Minimum Space: | 0.076mm (3mil) |

| Kushoma gomba saizi (yekupedzisira gomba): | 0.2mm |

| Chinongedzo chiyero: | 10: 1 |

| Kukura kwegomba Saizi: | 0.2-0.65mm |

| Kudhirowa kushivirira: | + \ - 0.05mm (2mil) |

| Kushivirira PTH: | Φ00.2-16mm + \ - 0.075mm (3mil) Φ1.6-6.3mm + \ - 0.1mm (4mil) |

| Npth kushivirira: | Φ00.2-16mm + - 0.05mm (2mil) Φ1.6-6.3mm + \ - 0.05mm (2mil) |

| Kupedzisa Bhodhi Kutsungirira: | Gobvu <0.8mm, kushivirira: +/-08mm |

| 0.8mm≤ticks≤6.5mm, kushivirira + /- 10% | |

| Minimum Soldermask Bridge: | 0.076mm (3mil) |

| Kusvetuka uye kukotama: | ≤0.75% Min0.5% |

| Raneg weTG: | 130-215 ℃ |

| Kutsungirira Kutsungirira: | +/- 10%, min +/- 5% |

| Kumusoro Kurapwa: | Hasl, lf hal |

| Kunyudzwa goridhe, goridhe remhepo, goridhe remunwe | |

| Kunyudzwa sirivha, kunyudzwa tin, op | |

| Inosarudza goridhe plating, goridhe rakakomberedza kusvika ku3um (120u ") | |

| Kabhoni kudhinda, peelable s / m, enpig | |

| Aluminium Board Kugona | |

| Nhamba yezvikamu: | Imwe chete denderedzwa, maviri matanda |

| Maximum Board Saizi: | 1500 * 600mm |

| BHUKU BHUKU: | 0.5-3.0mm |

| Mhetere yemhangura: | 0.54oz |

| Chikuru gomba saizi: | 0.8mm |

| Minimum Yakakura: | 0.1mm |

| Minimum Space: | 0.12mm |

| Minimum Pad size: | 10 Micron |

| Kumusoro Kupedzisa: | Hasl, OSP, Engiig |

| Kuumba: | CNC, kupuruzira, V-kutemwa |

| Zvepfungwa: | Tester Universal Tester |

| Kubhururuka probe yakavhurika / pfupi tester | |

| Simba rakakwirira microscope | |

| Kusungwa kweTesting Kit | |

| Peel Simba Tester | |

| Yakakwira volt yakavhurika & pfupi tester | |

| Cross Chikamu chinogunun'una kit nePolisher | |

| FPC kugona | |

| Zvikamu: | 1-8 materers |

| BHUKU BHUKU: | 0.05-0.5mm |

| Mhetere yemhangura: | 0.5-3oz |

| Minimum Yakakura: | 0.075mm |

| Minimum Space: | 0.075mm |

| In kuburikidza nehukuru hwegomba: | 0.2mm |

| Minimum LASER GOLLE Saizi: | 0.075mm |

| Minimum Punching Glot Saizi: | 0.5mm |

| Soldermask kushivirira: | + \ - 0.5mm |

| Minimuminodzeka kuderera kwekushivirira: | + \ - 0.5mm |

| Kumusoro Kupedzisa: | Hasl, LF Hasl, Kunyudzwa Sirivha, Kunyudzwa Goridhe, Goridhe Goridhe, Osp |

| Kuumba: | Kupuruzira, laser, chema |

| Zvepfungwa: | Tester Universal Tester |

| Kubhururuka probe yakavhurika / pfupi tester | |

| Simba rakakwirira microscope | |

| Kusungwa kweTesting Kit | |

| Peel Simba Tester | |

| Yakakwira volt yakavhurika & pfupi tester | |

| Cross Chikamu chinogunun'una kit nePolisher | |

| Rigid & Flex Kugona | |

| Zvikamu: | 1-28 matanda |

| Type Type: | Fr-4 (High Tg, Halogen Free, High Frequency) Ptfe, BT, GEK, ATuminium Base, Copper Base, KB, Nanya, Ilm, ISOLA, NALCO, Arlon |

| BHUKU BHUKU: | 6-240mil / 0.15-6.0mm |

| Mhetere yemhangura: | 210um (6oz) yeMukati Layer 210um (6oz) yeOnder Layer |

| Min mechanical Drill Saizi: | 0.2mm / 0.08 " |

| Chinongedzo chiyero: | 2: 1 |

| Max Panel Saizi: | Sigle side kana kaviri mativi: 500mm * 1200mm |

| Multilayer maratari: 508mm x 610mm (20 "x 24") | |

| Min mutsara upamhi / nzvimbo: | 0.076mm / 0.076mm (0.003 "/ 0.003") / 3mil / 3mil |

| Kuburikidza neHole Type: | Bofu / kuvigwa / plugged (VOP, VIP ...) |

| HDI / Microvilia: | EHE |

| Kumusoro Kupedzisa: | Hasl, lf hal |

| Kunyudzwa goridhe, goridhe remhepo, goridhe remunwe | |

| Kunyudzwa sirivha, kunyudzwa tin, op | |

| Inosarudza goridhe plating, goridhe rakakomberedza kusvika ku3um (120u ") | |

| Kabhoni kudhinda, peelable s / m, enpig | |

| Kuumba: | CNC, kupuruzira, V-kutemwa |

| Zvepfungwa: | Tester Universal Tester |

| Kubhururuka probe yakavhurika / pfupi tester | |

| Simba rakakwirira microscope | |

| Kusungwa kweTesting Kit | |

| Peel Simba Tester | |

| Yakakwira volt yakavhurika & pfupi tester | |

| Cross Chikamu chinogunun'una kit nePolisher | |