PCB Gungano Equipment

ANKE PCB inopa sarudzo yakakura yemidziyo yeSMT inosanganisira manual, semi-otomatiki uye zvizere otomatiki stencil printers, pick & place machines pamwe nebenchtop batch uye yakaderera kusvika yepakati-vhoriyamu reflow oveni yekusangana kwepamusoro gomo.

Pa ANKE PCB isu tinonzwisisa zvizere kunaka ndicho chinangwa chekutanga chePCB kusangana uye kukwanisa kuzadzisa iyo-ye-iyo-iyo nzvimbo inoteedzera yazvino PCB yekugadzira uye midziyo yegungano.

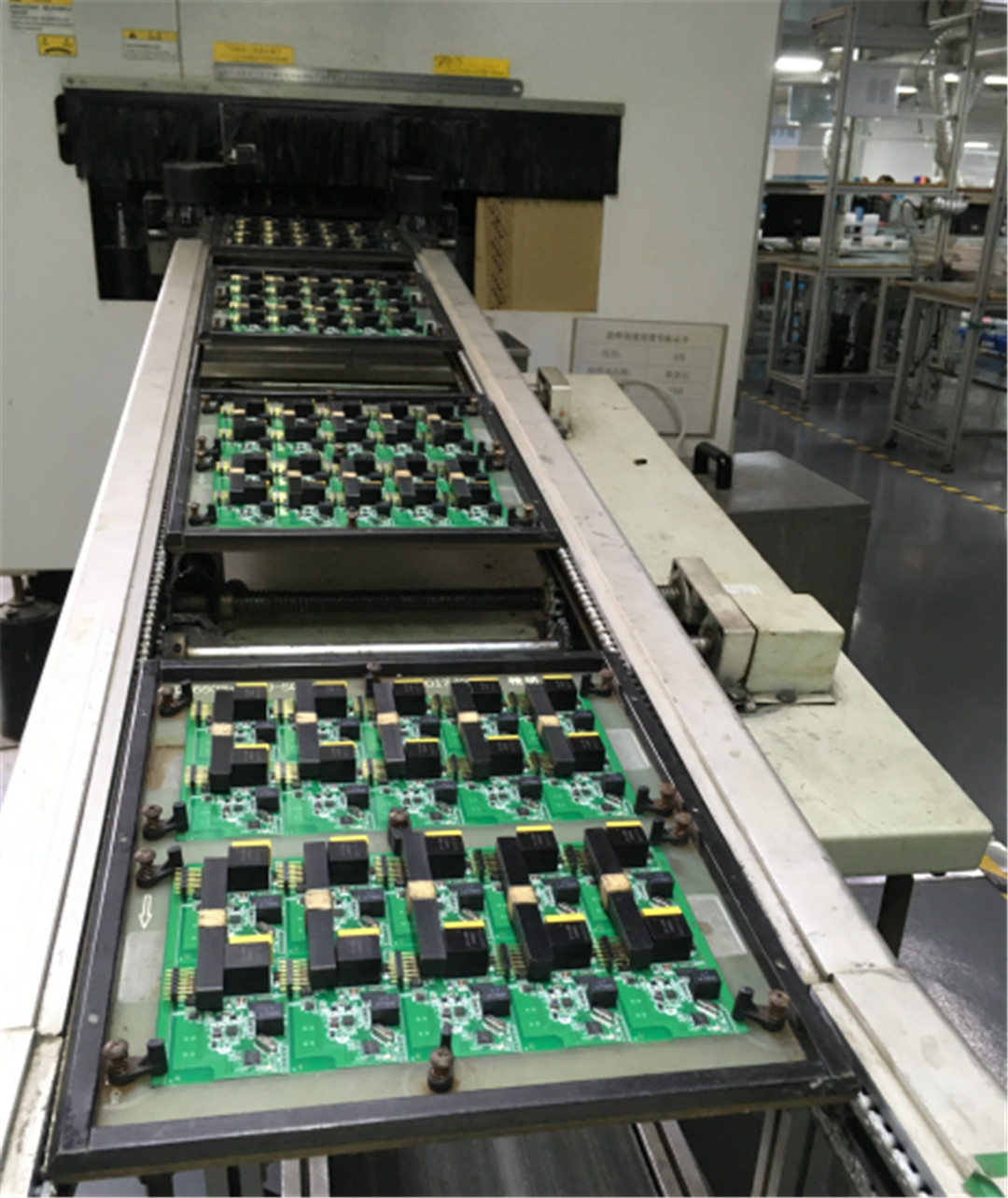

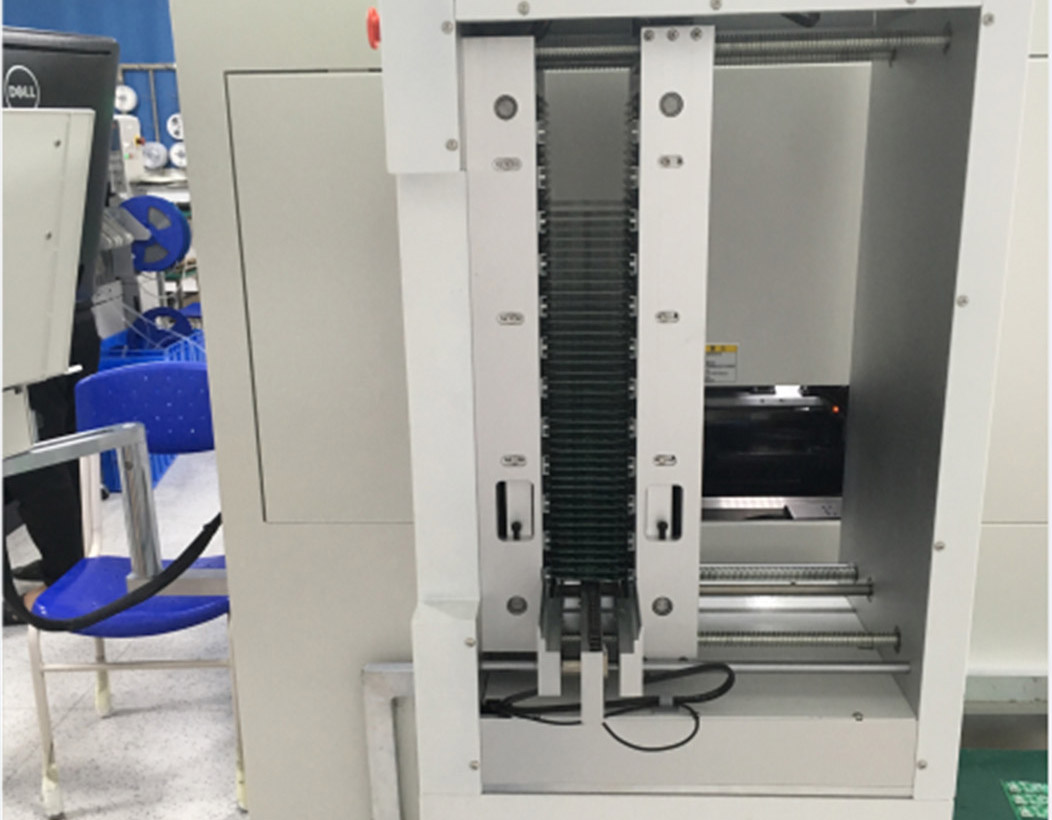

Otomatiki PCB loader

muchina uyu unobvumira pcb mapuranga kudya kupinda otomatiki solder namira kudhinda muchina.

Advantage

• Kuchengetedza nguva yevashandi

• Kuchengetedza mari mukugadzirwa kwegungano

• Kuderedza kukanganisa kunokwanisika kunozokonzerwa nemanyorero

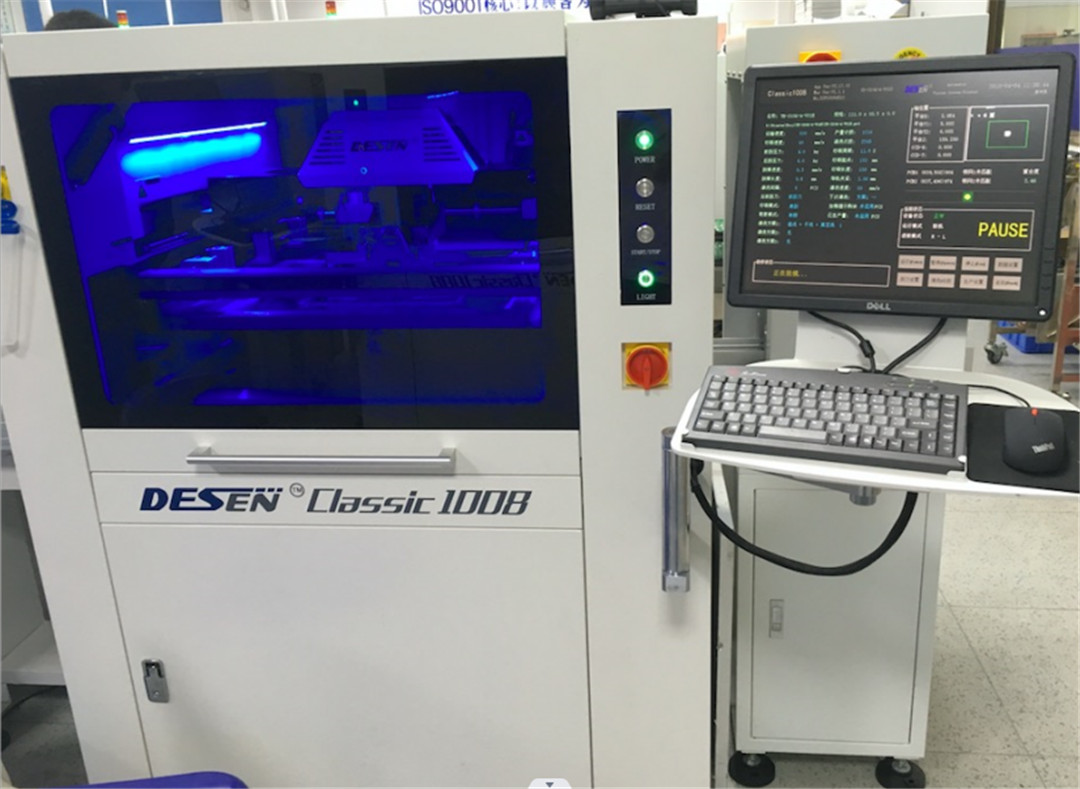

Otomatiki Stencil Printer

ANKE ine zvigadzirwa zvepamberi senge otomatiki stencil printer michina.

• Programmable

• Squeegee system

• Stencil otomatiki chinzvimbo hurongwa

• Yakazvimirira yekuchenesa system

• PCB kutamisa uye chinzvimbo hurongwa

• Easy-to-kushandisa interface humanized Chirungu / Chinese

• Mufananidzo wekutora hurongwa

• 2D kuongorora & SPC

• CCD stencil alignment

SMT Pick & Nzvimbo Machina

• Kurongeka kwepamusoro uye kuchinjika kwepamusoro kwe01005, 0201, SOIC, PLCC, BGA, MBGA, CSP, QFP, kusvika painonzwika 0.3mm

• Non-contact linear encoder system yekukwirira kudzokororwa uye kugadzikana

• Smart feeder system inopa otomatiki feeder chinzvimbo chekutarisa, otomatiki chikamu kuverenga, kugadzira data traceability

• COGNEX alignment system "Vision on the Fly"

• Pazasi chiono kurongeka sisitimu yepitch yakanaka QFP & BGA

• Yakakwana kune diki & yepakati vhoriyamu kugadzirwa

• Yakavakwa-mukati kamera system ine auto smart fiducial mark kudzidza

• Dispenser system

• Kuongororwa kwechiratidzo pamberi uye mushure mekugadzirwa

• Universal CAD kutendeuka

• Chiyero chekuisa: 10,500 cph (IPC 9850)

• Ball screw masisitimu mu X- uye Y-axes

• Inokodzera 160 akangwara auto tepi feeder

Kutungamira-Mahara Reflow Ovheni/Kutungamira-Mahara Reflow Soldering Machine

•Windows XP oparesheni software ine maChinese neChirungu mamwe.The yose hurongwa pasi

kusanganisa kutonga kunogona kuongorora uye kuratidza kutadza.Yese data yekugadzira inogona kuchengetwa zvachose uye kuongororwa.

• PC&Siemens PLC inodzora unit ine kuita kwakagadzikana;Kunyatsoita kudzokororwa kweprofile kunogona kudzivirira kurasikirwa kwechigadzirwa kunokonzerwa nekusashanda zvakanaka kwekombuta.

• Iyo yakasarudzika dhizaini yekupisa yekupisa kwenzvimbo dzekupisa kubva kumativi mana inopa kupisa kwakanyanya;mutsauko wepamusoro-tembiricha pakati pe2 nzvimbo dzakabatana zvinogona kudzivirira kupindira kwekushisa;Inogona kupfupisa mutsauko wekushisa pakati pehukuru-saizi uye zvidiki zvikamu uye kusangana neiyo solder inoda yePCB yakaoma.

• Kutonhodza mhepo yekumanikidzira kana kutonhodza mvura ine sipidhi yakanaka yekutonhodza inokodzera marudzi ese akasiyana emutobvu asina solder paste.

• Kuderedza simba rekushandisa (8-10 KWH / awa) kuchengetedza mari yekugadzira.

AOI (Automated Optical Inspection System)

AOI mudziyo unoona zvakakanganisika mukugadzira welding zvichibva pamitemo yekuona.AOl tekinoroji iri kubuda yekuyedza, asi iri kukura nekukurumidza, uye vagadziri vazhinji vakatangisa midziyo yekuongorora yeAl.

Munguva yekuongorora otomatiki, muchina unotarisa otomatiki PCBA kuburikidza nekamera, inounganidza mifananidzo, uye inoenzanisa yakaonekwa solder majoini neanokwanisa paramita mudhatabhesi.Repairman kugadzirisa.

Yepamusoro-kumhanya, yakakwirira-chaiyo yekuona yekugadzira tekinoroji inoshandiswa kuona otomatiki zvikanganiso zvakasiyana-siyana zvekuisa uye kukanganiswa kwekutengesa paPB board.

Mapuranga ePC anotangira kubva kune yakanaka-pitch yakakwirira-density mabhodhi kusvika kune yakaderera-density yakakura-saizi mabhodhi, achipa in-line yekuongorora mhinduro yekuvandudza kugadzirwa kwemhando uye mhando yevatengesi.

Nekushandisa AOl semudziyo wekudzikisa hurema, zvikanganiso zvinogona kuwanikwa uye kubviswa pakutanga kwegungano, zvichikonzera kutonga kwakanaka kwemaitiro.Kukurumidza kuonekwa kwezvakaremara kunodzivirira kuti mapuranga akaipa atumirwe kumatanho egungano anotevera.AI ichadzikisa mari yekugadzirisa uye kudzivirira kurasa mapuranga kupfuura kugadziriswa.

3D X-Ray

Nekukurumidza kuvandudzwa kwehunyanzvi hwemagetsi, iyo miniaturization yekurongedza, yakakura-density gungano, uye kuenderera kunoramba kuchibuda kweakasiyana siyana matekinoroji ekurongedza, zvinodiwa zvemhando yegungano redunhu zviri kuramba zvichikwira nekukwira.

Naizvozvo, zvinodiwa zvepamusoro zvinoiswa panzira dzekuona uye matekinoroji.

Kuti zvizadzise zvinodiwa izvi, matekinoroji matsva ekuongorora ari kuramba achibuda, uye 3D otomatiki X-ray yekuongorora tekinoroji mumiriri akajairika.

Haikwanise kungoona majoini asingaoneki ekutengesa, akadai seBGA (Ball Grid Array, ball grid array package), nezvimwewo, asi zvakare ita ongororo yemhando yepamusoro uye yehuwandu hwemhedzisiro yekutsvaga kuti uwane kukanganisa nekukurumidza.

Parizvino, akasiyana siyana ebvunzo matekinoroji anoshandiswa mumunda wekuedzwa kwegungano remagetsi.

Kazhinji midziyo ndeye Manual visual inspection (MVI), In-circuit tester (ICT), uye Automatic Optical.

Kuongorora (Otomatiki Optical Inspection).AI), Automatic X-ray Inspection (AXI), Functional Tester (FT) nezvimwewo.

PCBA Rework Station

Nezve iyo rework process yeungano yese yeSMT ine chekuita, inogona kukamurwa kuita matanho akati wandei senge desoldering, component reshaping, PCB pad yekuchenesa, componement placement, welding, nekuchenesa.

1. Desoldering: Iyi nzira ndeyekubvisa zvakagadziriswa zvikamu kubva kuPB yezvakagadziriswa zveSMT zvikamu.Iyo inonyanya kukosha musimboti haisi yekukuvadza kana kukuvadza izvo zvakabviswa izvo, zvakatenderedza zvikamu uye PCB pads.

2. Kuumbwa kwechikamu: Mushure mokunge zvikamu zvakagadziriswa zvaparadzwa, kana iwe uchida kuramba uchishandisa zvikamu zvakabviswa, unofanira kugadzirisa zvakare zvikamu.

3. PCB pad yekuchenesa: PCB pad yekuchenesa inosanganisira padhi yekuchenesa uye kugadzirisa basa.Pad leveling inowanzoreva kuenzana kwePCB pad pamusoro pechigadzirwa chakabviswa.Pad yekuchenesa kazhinji inoshandisa solder.Chishandiso chekuchenesa, senge simbi yekunyungudutsa, inobvisa yakasara solder kubva pamapadhi, yobva yapukuta nedoro rakazara kana munyungudutsa unotenderwa kubvisa faindi uye zvakasara zvinoyerera.

4. Kuiswa kwezvikamu: tarisa PCB yakagadziridzwa nekadhindwa solder paste;shandisa chikamu chekuisa mudziyo weiyo rework station kusarudza yakakodzera vacuum nozzle uye gadzirisa PCB yekumisikidza ichaiswa.

5. Soldering: Iyo soldering process ye rework inogona kukamurwa kuita manual soldering uye reflow soldering.Inoda kunyatsotariswa kunoenderana nechikamu uye PB marongerwo ezvivakwa, pamwe chete nezvimiro zvewelding zvinhu zvinoshandiswa.Manual welding iri nyore uye inonyanya kushandiswa kugadzirazve welding yezvikamu zvidiki.

Lead-Mahara Wave Soldering Machine

• Bata skrini + PLC control unit, iri nyore uye yakavimbika kushanda.

• External streamlined design, mukati modular dhizaini, kwete chete yakanaka asiwo nyore kuchengeta.

• The flux sprayer inogadzira yakanaka atomization ine yakaderera flux kushandiswa.

• Turbo fan inopedza nekudzivirira keteni kudzivirira kupararira kweatomidhi inoyerera munzvimbo yepreheating, kuve nechokwadi chekushanda kwakachengeteka.

• Modularized hita preheating yakanakira kugadzirisa;PID inodzora kupisa, tembiricha yakagadzikana, yakatsetseka curve, gadzirisa kuoma kwe lead-isina maitiro.

• Solder pani dzinoshandisa yakakwirira-simba, isina-deformable cast iron inobereka hukuru hwepamusoro hwekupisa.

Manozzles akagadzirwa netitanium anovimbisa yakaderera thermal deformation uye yakaderera oxidation.

• Iine basa rekutanga nguva yakatarwa uye kuvhara kwemuchina wose.