Zvigadzirwa

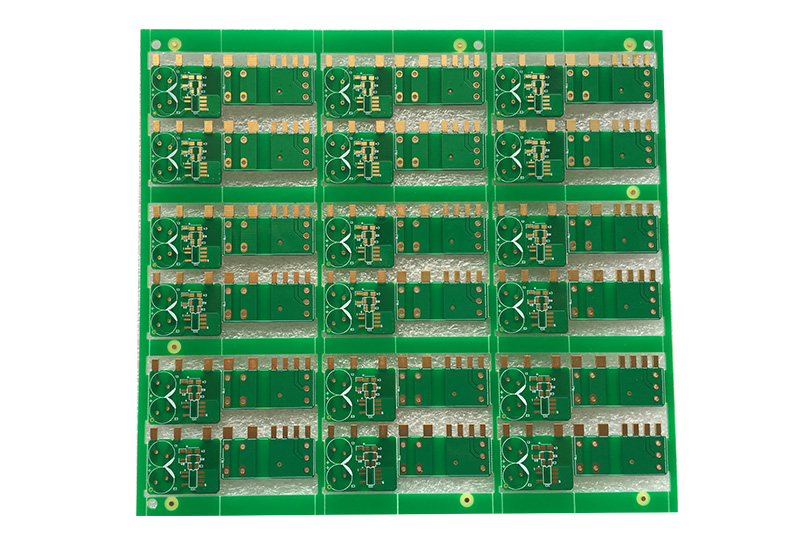

Edge plating 6 layer PCB yeIHT main board

| Materers | 6 matanda |

| Bhodhi ukobvu | 1.60mm |

| Zvinhu | Fr4 TG170 |

| Copper Bickness | 1./1/1/1/1 Oz (35um) |

| Kumusoro Kupedzisa | Enig Au Kuzeya 0.05um; Bickness 3um |

| Min gomba (mm) | 0.203mm yakazadzwa neyein |

| Min mutsara upamhi (mm) | 0.13mm |

| Min Line Space (MM) | 0.13mm |

| Sengesa Mask | Girinhi |

| LEGEND COUL | Chena |

| Mechancal kugadzirisa | V-Kurova, CNC Kugaya (Kuenderera) |

| Kurongedza | Anti-static bag |

| E-bvunzo | Kubhururuka probe kana chidimbu |

| Kugamuchirwa Standard | IPC-A-600H Kirasi 2 |

| Application | Zvemagetsi emagetsi |

Zvigadzirwa zvechigadzirwa

Semutengesi wePCB akasiyana PCB, Mavhoriyamu, tungamira nguva sarudzo, isu tine sarudzo yeiyo bandwidth yemhando dzakasiyana dzePCB dzinogona kuvharwa uye dzinogara dziripo mumba.

Zvatinoda kune zvimwe kana zvezvinhu zvakakosha zvinogona zvakare kusangana kazhinji, asi, zvichienderana nezvinodiwa chaizvo, kusvika pamazuva gumi ekushanda vanogona kudikanwa kuti vatore zvinhu.

Ita kuti ubatane nesu uye ukurukure zvaunoda neimwe yeyekutengesa kana cam timu.

Zvigadzirwa zvakajairika zvakabatwa mu stock:

| Zvikamu | Ukobvu | Kushivirira | Weave Type |

| Zvemukati matare | 0,05mmm | +/- 10% | 106 |

| Zvemukati matare | 0.10mm | +/- 10% | 2116 |

| Zvemukati matare | 0,13mmm | +/- 10% | 1504 |

| Zvemukati matare | 0,15mm | +/- 10% | 1501 |

| Zvemukati matare | 0.20mm | +/- 10% | 7628 |

| Zvemukati matare | 0,25mm | +/- 10% | 2 x 1504 |

| Zvemukati matare | 0.30mm | +/- 10% | 2 x 1501 |

| Zvemukati matare | 0.36mm | +/- 10% | 2 x 7628 |

| Zvemukati matare | 4,41mm | +/- 10% | 2 x 7628 |

| Zvemukati matare | 0,51mm | +/- 10% | 3 x 7628/2116 |

| Zvemukati matare | 0,61mm | +/- 10% | 3 x 7628 |

| Zvemukati matare | 0.71mm | +/- 10% | 4 x 7628 |

| Zvemukati matare | 0,80mm | +/- 10% | 4 x 7628/1080 |

| Zvemukati matare | 1,0mm | +/- 10% | 5 x7628 / 2116 |

| Zvemukati matare | 1,2mm | +/- 10% | 6 x7628 / 2116 |

| Zvemukati matare | 1,55mmm | +/- 10% | 8 x7628 |

| Prepregs | 0.058mm * | Zvinoenderana nemaratidziro | 106 |

| Prepregs | 0.084mm * | Zvinoenderana nemaratidziro | 1080 |

| Prepregs | 0.112mm * | Zvinoenderana nemaratidziro | 2116 |

| Prepregs | 0.205mm * | Zvinoenderana nemaratidziro | 7628 |

Cu gobvu pamusoro wemukati wemukati: standard - 18μm ne 35 μm,

PaKukumbira 70 μM, 105μm uye 140μm

Type Type: Fr4

TG: Approx. 150 ° C, 170 ° C, 180 ° C

εr pa 1 mz: ≤5,4 (yakajairika: 4,7) inowanikwa pane chikumbiro

Stackup

Iyo huru 6 layer stackup inogadziriswa ichave kazhinji sepazasi:

·

· Mukati

· Washington

Simba

· Mukati

· Kuti

Q & A nzira yekuongorora gomba remadziro tensile uye zvakabatana zvakatemwa

Maitiro Ekuedza Hole Wall Tensile uye Yakanangana Nyaya? Gomba remadziro rinobvisa zvikonzero uye mhinduro?

Holl wall Bull bvunzo yakaiswa kare ye-eble-eble zvikamu kuti usangane zvinodiwa pakugadzira. Muedzo weKuyedzwa ndewekutengesa waya pane PCB bhodhi kuburikidza nemakomba uye wozoyera iyo inoburitsa kukosha kwemamita yekushushikana. Zvinoenderana nezvakaitika, tsika dzakawanda dzakakwira kwazvo, dzinoita kuti dzisave nematambudziko mukushandisa. Zvigadzirwa zvakatemwa zvinosiyana zvichienderana

kune zvakasiyana zvinodiwa, zvinokurudzirwa kunongedzera kuIPC zvine chekuita neIPC zvirevo.

Rwekuparadzanisa kweHolar Ruparidziro dambudziko renyaya yerariki yekudyidzana, izvo zvinowanzo kukonzerwa nezvikonzero zviviri zvakajairika, chekutanga chibatiso chevarombo esmaar (Desmar) inoita kuti kushushikana hakuna kukwana. Imwe yacho ndeye iyo yemhangura yemhangura phongwe kana yakanangana negoridhe, semuenzaniso: kukura kwehana, bulky stack kuchaguma nekushambadzirwa kwevarombo. Ehe pane zvimwe zvinhu zvinogona kuitika zvinogona kukanganisa dambudziko rakadaro, zvisinei izvi zvinhu zviviri ndidzo dzinonyanya kuzivikanwa.

Pane zvikanganiso zviviri zvekuparadzaniswa kwegomba Kana dambudziko iri rikaoma kugadzirisa, pamwe unofanirwa kuchinja zvinyorwa zvekusimbisa kuti usangane nekuvandudzwa.

Kana isiri dambudziko iri pamusoro, rinonyanya kukonzerwa nekudzikisira kwegomba remhangura uye gomba remadziro. Zvikonzero zvinokwanisika zvechikamu ichi chinosanganisira kusarongeka kwemadziro egomba, zvakawandisa zvemakemikari ndarira, uye kuremara kwakakonzerwa nekukonzerwa nemakemikari emhangumari yemhangura. Izvi ndizvo zvese chikonzero chinogoneka. Ehezve, kana mhando yekukweva iri murombo, chimiro chesiyano yemadziro egomba anogona kukonzerawo matambudziko akadaro. Kana dziri basa rekutanga kugadzirisa matambudziko aya, rinofanira kutanga ratidza kuti mudzive unokonzeresa uye wobva wabata neiyo sosi yechikonzero chisati chambogadziriswa zvachose.