PCB mushandirapamwe

ANKE PCB offers a large selection of SMT equipment including manual, semi-automatic and fully automatic stencil printers, pick&place machines as well as benchtop batch and low to mid-volume reflow ovens for surface mount assembly.

KuAnke PCB isu tinonyatsonzwisisa mhando yekambani yepcb uye inokwanisa kuita iyo State-ye-iyo-iyo-iyo-iyo-ye-art nzvimbo yePCB Fibrairthation uye Zvishandiso zveAystem.

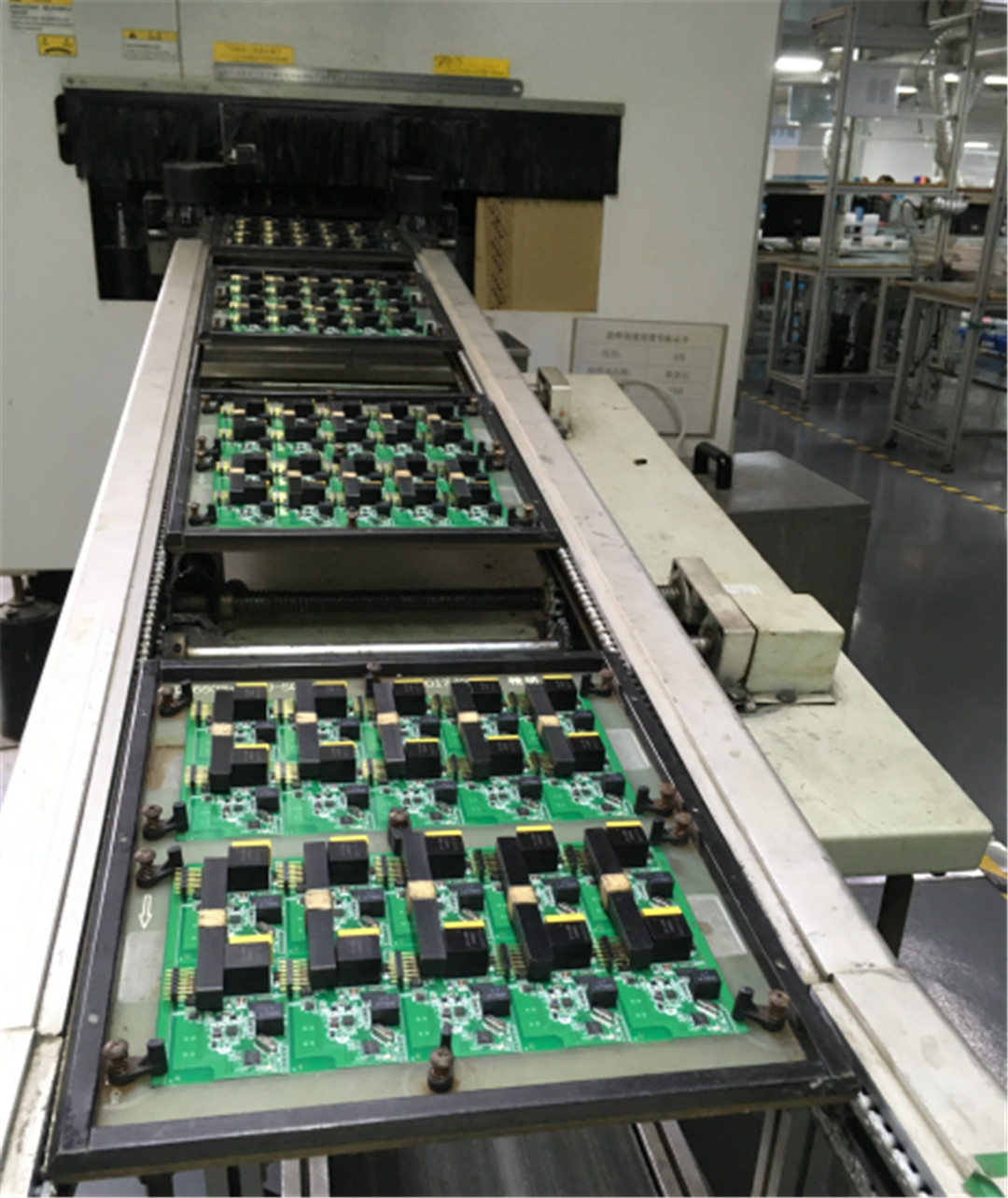

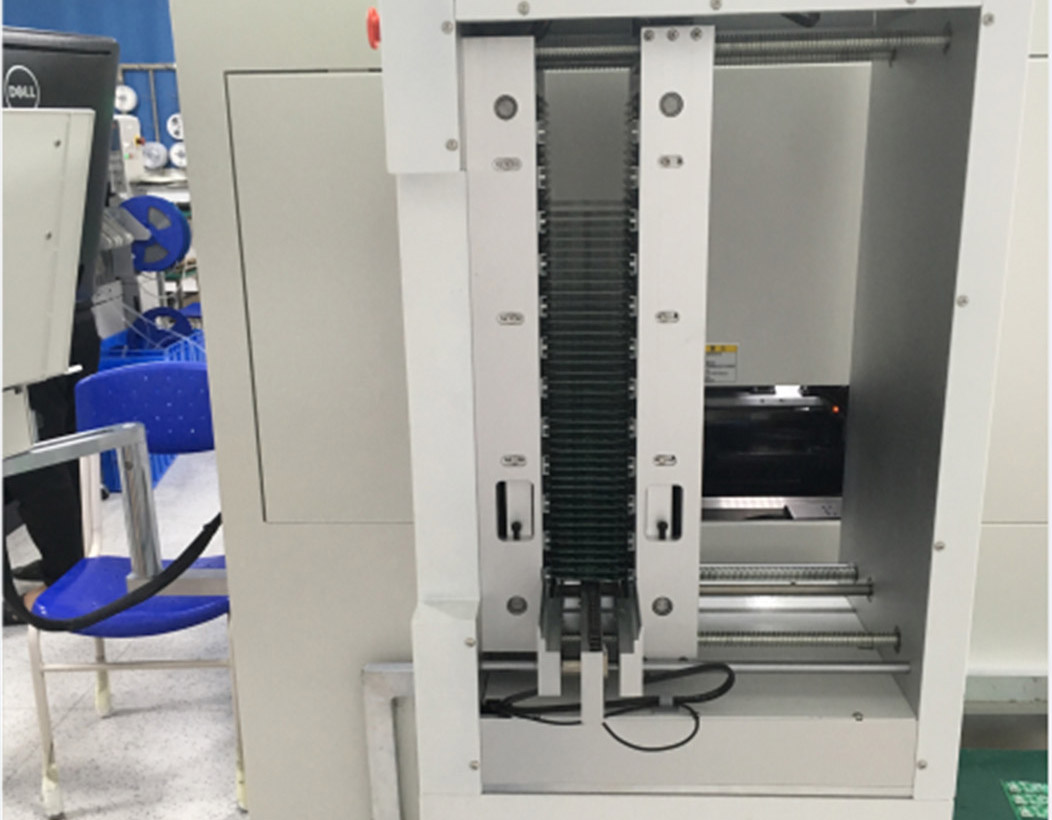

Otomatiki PCB Loader

Muchina uyu unobvumira PCB mabhodhi ekudyisa mumutengesi otomatengesa paste muchina wekudhinda.

Mukana

• Nguva kuchengetedza kune vashandi vebasa

• Mari yekuchengetedza mukugadzirwa kwegungano

• kuderedza kukanganisa kunogona kukonzerwa nebhuku racho

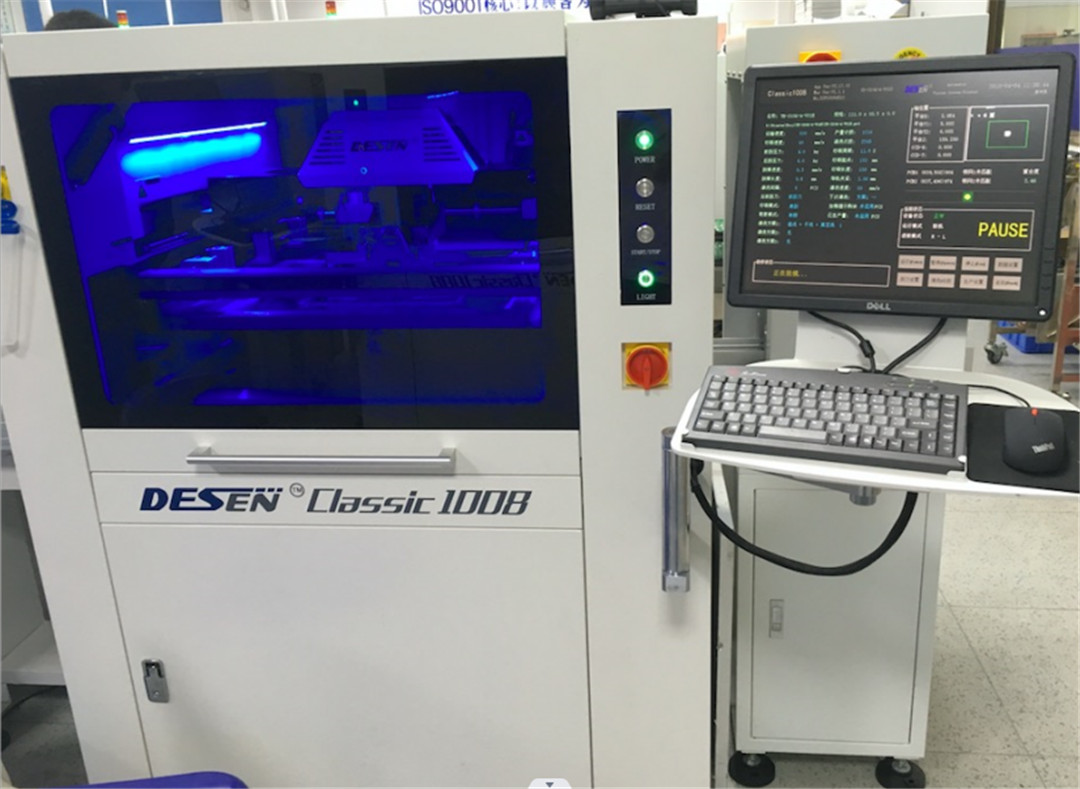

Otomatiki stencil printer

Anke ane midziyo yekufambisa senge otomatiki stencil printer michina.

• zvinorongwa

• Squeegee system

• Stencil otomatiki chinzvimbo system

• Yakazvimirira kuchenesa system

• PCB kuendesa uye chinzvimbo system

• Easy-yekushandisa interface Hunhu hweChirungu / Chinese

• Mufananidzo wekutora system

• 2D kuongorora & SPC

• CCD stencil alignment

Smt pick & nzvimbo michina

• Yakanyanya kurongeka uye yakanyanya kushanduka ye1005, 0201, soic, plcc, bga, mbga, qfp, kusvika kune yakanaka-pitch 0.3mm

• isiri-yekubika mutsara Encoder system yekudzokorora kwakanyanya uye kugadzikana

• Smart Feeder System inopa otomatiki Feedter chinzvimbo kutarisa, otomatiki componation kuverenga, kugadzirwa kwedatha data rekutengesa

• Cognex alignment system "chiratidzo pane kubhururuka"

• Pasi Pazasi Vision Alignment System yeFinki Pitch QFP & BGA

• Yakakwana kune zvidiki & pakati vhoriyamu yekugadzirwa

• Yakavakwa-muCherudzi system ine auto Smart Fiducial Mako kudzidza

• Dispenser system

• Kuona kuongorora isati yasvika uye mushure mekugadzirwa

• Universal Cad Shanduko

• Kuiswa Kwekuiswa Kwemakore: 10,500 CPH (IPC 9850)

• bhora screw system mu x- uye y-axes

• yakakodzera kune 160 akangwara auto tepi feeder

Tungamira-Yemahara Rehore Oven / Kutungamira-Yemahara Rehers Interering Machine

• Windows XP kushanda software neChinese neChirungu dzimwe nzira. Iyo yese system pasi

Kubatanidza kudzora kunogona kuongorora uye kuratidza kutadza. Yese data yekugadzira inogona kuponeswa zvachose uye kuongororwa.

• PC & Nokia S60 PLC Kudzora Chikamu neNzvimbo Yakagadzikana Performance; Yakakura chaiyo yekudzokorora nhoroondo inogona kudzivirira kurasikirwa kwechigadzirwa kunorevedzwa kusvika pakunyora kwekombuta.

• iyo yakasarudzika dhizaini yeiyo inobata convection yemasangano ekudziya kubva pamativi mana anogovera zvakakwirira kupisa kugona; Musiyano wakanyanya-tembiricha pakati pe2 makonzo nzvimbo dzinogona kudzivirira tembiricha yekukanganisa; Inogona kupfupisa musiyano wekupisa pakati pehukuru-hukuru uye zvidiki zvikamu uye sangana neyekutengesa kudiwa kwePCB YEMAHARA.

• Kumanikidzwa kwemhepo kutonhora kana mvura inotonhorera chiller ine zvakanaka kutonhora kumhanya kunokwira marudzi ese akasiyana ekutungamira mahara mahara.

• Yakadzika masimba masimba (8-10 mk / awa) kuchengetedza iyo yekugadzira mutengo.

AOI (automated Optical Ongorora system)

Aoi chishandiso chinoona zvikanganiso zvakajairika mukugadzirwa kwehutachiona zvichibva pamhosva dzechokwadi. AOL ndeyekupaza kwehunyanzvi hwekuedza, asi kuri kukudziridza nekukurumidza, uye vagadziri vazhinji vakatanga kuedza al kuyedza zvishandiso.

Munguva yekuongorora otomatiki, muchina wacho unongotarisa PCBA kuburikidza nekamera, inounganidza mifananidzo, uye inofananidza mutengesi anoonekwa nemaharimita anokwanisa mudhata. Kugadzirisa.

Yakakwira-kumhanya, yakakwirira-chaiyo-chaiyo yekugadzirisa tekinoroji inoshandiswa kuchaona zvakaringana kuiswa zvikanganiso uye kutengesa zvikanganiso pane pb board.

Mabhodhi ePC kubva pane zvakanaka-pitch-density mabhodhi kusvika akaderera-density mabhodhi akakura-size

Nekushandisa AOL seyakaremara kudzora chishandiso, zvikanganiso zvinogona kuwanikwa uye zvikabviswa pakutanga mukuita kwegungano, zvichikonzera mukutonga kwakanaka. Kubvira pakuremara kwezvirukwa kuchadzivirira mapuranga akaipa kubva pakutumirwa kunzvimbo yakatevera gungano. AI ichaderedza mari yekugadzirisa uye kudzivirira kuputira mabhodhi zvisingagadziriswe.

3d x-ray

Nekuvandudza nekukurumidza kwehunyanzvi hwemagetsi, miniatanga yegungano rekutakura, kuungana kwepamusoro-soro, uye zvinodikanwa zvematongerwo enyika akasiyana siyana, izvo zvinodiwa nemhando yeDunhu iri ichikwira uye yakakwira.

Naizvozvo, zvakakwirira zvinodiwa zvinoiswa pane nzira dzekuona uye matekinoroji.

Kuti tisangane ichi chinodiwa, tekinoroji matsva ekuongorora anogara achibuda, uye 3d otomatiki X-Ray Ongcturction tekinoroji chaiyo mumiriri akajairwa.

Izvo hazvigone chete kuona zvisingaoneki vaisarengeserana majoini, senge bga (bhora grid array array, etc.,

Parizvino, maitiro akasiyana-siyana ekuongororwa anoiswa mumunda wekuedzwa kwemagetsi ekuedza.

Zvinowanzoitika zvigadzirwa zviratidzo zvekuona (MVVI), mu-Circuit Tester (ICT), uye otomatiki Optical

Kuongorora (otomatiki estical kuongorora). AI), otomatiki X-ray ongororo (axi), inoshanda tester (ft) etc.

PCBA rework chiteshi

Kusvika pakubata kwebasa rose reSMT zvine basa, zvinogona kukamurwa kuita matanho akati wandei senge desolding, chikamu chevhu

1. Desoldingering: Iyi process ndeyekubvisa zvikamu zvakagadziriswa kubva kuPB yeiyo yakatarwa SMT zvikamu. Nheyo yakanyanya kukosha haina kukuvadza kana kukuvadza izvo zvakabviswa zvikamu, zvikamu zvakatenderedza uye PCB mapads.

2..

3. PCB Pad Kuchenesa: PCB Pad Kuchenesa kunosanganisira Pad kuchenesa uye kusarudzika basa. Pad Lighting kazhinji inoreva kuunganidzwa kwePCB pad pamusoro peiyo yakabviswa mudziyo. Pad kuchenesa kazhinji kunoshandisa murindiri. Chishandiso chekuchenesa, chakadai sedare rekuchenesa, rinobvisa mutengesi akasara kubva pamapuru, anobva apukutuka aine doro zvachose kana rakabvumidzwa kuti abvise faindi uye yakasara flux zvikamu.

4 Shandisa chidimbu chekuisa chishandiso chechiteshi chebasa kuti usarudze iyo yakakodzera vacuum nouzzle uye gadzirisa iyo rework yeChinzvimbo kuiswa.

5. Kutengeserana: Maitiro ekutengesa ekurhanda anoshanda anogona kukamurwa mukuita kuti agone kutengesa uye kuderedza vatengeserero. Inoda kunyatsofungisisa zvichienderana nechikamu uye pb liyut zvivakwa, pamwe nezvivakwa zvezvinhu zvinoshandiswa. Manual welding ndeye yakapfava uye inonyanya kushandiswa kuti igadziriswe nelting zvidiki zvikamu.

Kutungamira-Yemahara Wazita Scums SCY

• Kubata Screen + PLC kutonga kweyuniti, iri nyore uye yakavimbika kushanda.

• Kugadziriswa kwekunze kwekunze, zvemukati modular dhizaini, kwete chete yakanaka chete asi zvakare nyore kuchengetedza.

• Iyo flux sprayer inoburitsa tomization yakanaka neyakaderera flux yekushandisa.

• Turbo fan inopera nejira rekuvharidzira kuti udzivise kusiyana-siyana kwekutora flux munzvimbo yekunyepedzera, ichisimbisa yakachengeteka kushanda.

• Yakatema heyter inosimbisa inokonzeresa kugadzirisa; Pid control kupisa, tembiricha yakasimba, yakatsvedza curve, gadzirisa kuoma kwehurongwa hwekutungamira.

• Vanenge vachimanikidza mapuranga anoshandisa yakakwira-simba, isiri-inogadzirisa simbi simbi inoburitsa yepamusoro yekubata kwakanyanya.

Nozzles yakagadzirwa neTitanium simbisa yakaderera yekuparadza gadziriro uye yakaderera oxidation.

• Iyo ine basa re otomatiki nguva yakatarwa uye kuvhara yemuchina wese.