Kuita kugadzirisa uye kugadzirisa paPCBs kunogona kuwedzera hupenyu hwemaseketi.Kana PCB yakanganisa ikasangana panguva yegungano rePCB, bhodhi rePCB rinogona kugadziriswa zvichienderana nemhando yekusashanda.Pazasi pane dzimwe nzira dzekugadzirisa uye kugadzirisa maPCB.

1. Nzira yekuita sei kutonga kwehutano paPCB panguva yekugadzira?

Kazhinji, mafekitori ePCB ane michina yakasarudzika uye maitiro akakosha anogonesa kutonga kwemhando yePCB mukati mekugadzira maitiro.

1.1.Kuongorora kweAOI

Kuongorora kweAOI kunotarisisa otomatiki kuona zvinhu zvisipo, zvisizvo, nezvimwe zvakakanganisika paPCB.Midziyo yeAOI inoshandisa makamera kutora mifananidzo yakawanda yePCB uye inoaenzanisa nemareferensi board.Kana kusawirirana kunoonekwa, zvinogona kuratidza zvikanganiso zvinogona kuitika.

1.2.Flying Probe Testing

Kuongorora kubhururuka kunoshandiswa kuona mapfupi uye akavhurika maseketi, zvisizvo zvikamu (diode uye transistors), uye hurema mukudzivirira diode.Nzira dzakasiyana dzekugadzirisa PCB dzinogona kushandiswa kugadzirisa zvikabudura uye kukanganisa kwechikamu.

1.3.FCT Testing

FCT (Functional Test) inonyanya kutarisisa pakuyedzwa kunoshanda kwePCBs.Iwo ma paramita ekuyedza anowanzo kupihwa nevainjiniya uye anogona kusanganisira akareruka chinja bvunzo.Mune zvimwe zviitiko, software yakasarudzika uye maprotocol chaiwo anogona kudiwa.Kushanda kuyedza kunoongorora zvakananga kushanda kwePCB pasi pemamiriro ekunze epasirese.

2. Zvimwe Zvinokonzera PCB Kukuvadza

Kunzwisisa zvikonzero zvekutadza kwePCB kunogona kukubatsira nekukurumidza kuona kukanganisa kwePCB.Hezvino zvimwe zvinowanzoitika kukanganisa:

Kukundikana kwechikamu: Kutsiva zvikamu zvakakanganisika zvinogona kubvumira kuti dunhu rishande zvakanaka.

Overheating: Pasina kutonga kwakakodzera kwekupisa, zvimwe zvikamu zvinogona kupiswa.

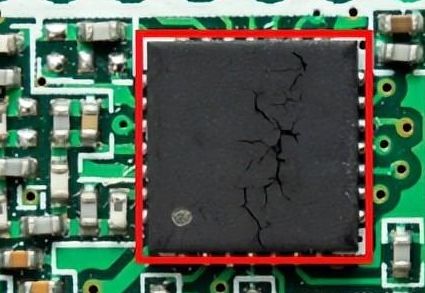

Kukuvadzwa mumuviri: Izvi zvinonyanya kukonzerwa nekubata kwakashata,

zvinotungamira mukutsemuka muzvikamu, majoini e solder, solder mask layer, trace, uye pads.

Kusvibiswa: Kana iyo PCB ikasangana nemamiriro ezvinhu akaomarara, mitsetse uye zvimwe zvikamu zvemhangura zvinogona kusvibiswa.

3. Sei Troubleshoot PCB Kukanganisa?

Mazita anotevera ndiwo 8 nzira:

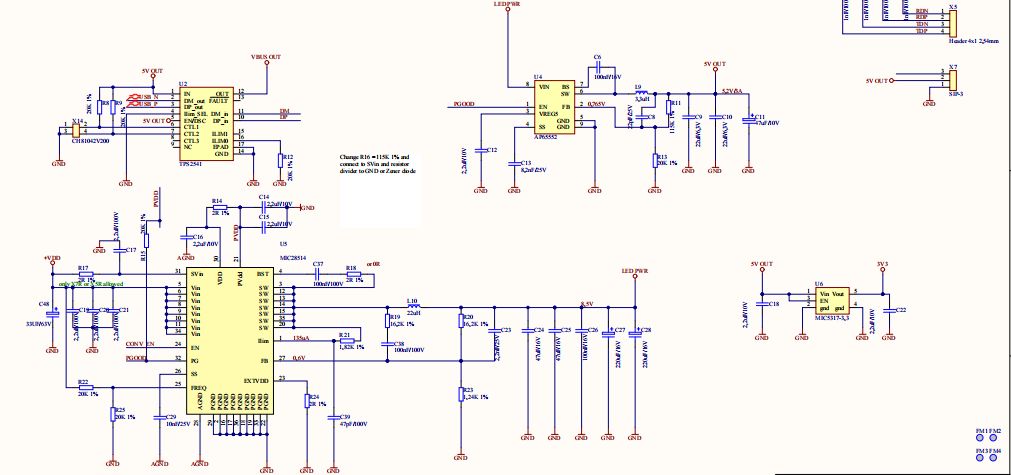

3-1.Nzwisisa hurongwa hwedunhu

Pane zvakawanda zvinoumba paPCB, zvakabatana kuburikidza nemhangura.Inosanganisira magetsi, pasi, uye zviratidzo zvakasiyana-siyana.Pamusoro pezvo, kune akawanda maseketi, senge mafirita, decoupling capacitors, uye inductors.Kunzwisisa izvi kwakakosha pakugadzirisa PCB.

Kuziva nzira yekutevera nzira yazvino uye kuparadzanisa zvikamu zvisina kunaka zvinotsamira pakunzwisisa redunhu schematic.Kana iyo schematic isingawanikwe, zvingave zvakafanira kudzosera mainjiniya schematic zvichienderana nePCB marongero.

3-2.Visual Inspection

Sezvambotaurwa, kupisa kwakanyanya ndechimwe chezvikonzero zvikuru zvekukanganisa kwePCB.Chero zvikamu zvakatsva, maronda, kana majoini ekutengesa anogona kuonekwa zviri nyore nemaziso kana pasina simba rekuisa.Mimwe mienzaniso yekukanganisa inosanganisira:

- Bulging / overlapping / zvisipo zvinoumba

- Discolored traces

- Cold solder joints

- Yakawandisa solder

- Tombstoned zvikamu

- Mapedhi akasimudzwa / akashaikwa

-Kutsemuka paPCB

Zvose izvi zvinogona kuonekwa kuburikidza nekuongorora kwekuona.

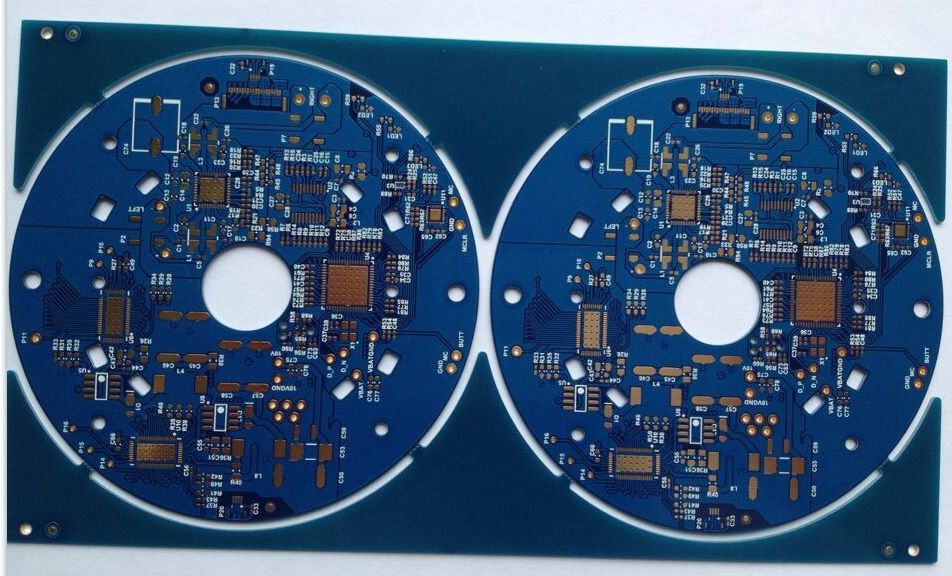

3-3.Enzanisa neIdentical PCB

Kana iwe uine imwe yakafanana PCB ine imwe inoshanda nemazvo uye imwe inokanganisa, zvinova nyore.Iwe unogona nekuona kuenzanisa zvikamu, misalignments, uye hurema mukutsvaga kana vias.Pamusoro pezvo, iwe unogona kushandisa multimeter kuti utarise iyo yekupinda uye inobuda kuverenga kwemabhodhi ese ari maviri.Hunhu hwakafanana hunofanirwa kuwanikwa sezvo maPCB maviri akafanana.

3-4.Isolate Faulty Components

Kana kuongorora kwekuona kusina kukwana, unogona kuvimba nemidziyo yakadai semultimeter kana LCR mita.Edza chimwe nechimwe chikamu pachezvake zvichibva pane datasheet uye dhizaini zvinodiwa.Mienzaniso inosanganisira resistors, capacitors, inductors, diodes, transistors, uye LEDs.

Semuenzaniso, unogona kushandisa diode kuseta pane multimeter kutarisa diode uye transistors.Iyo base-muunganidzi uye base-emitter junctions inoshanda sema diode.Kune akareruka edunhu bhodhi madhizaini, unogona kutarisa akavhurika uye mapfupi maseketi mune zvese zvinongedzo.Ingo seta mita kupikisa kana kuenderera modhi uye enderera kuyedza imwe neimwe yekubatanidza.

Paunenge uchiitisa cheki, kana kuverenga kuri mukati mezvirevo, chikamu chinoonekwa sechiri kushanda nemazvo.Kana kuverenga kwacho kusina kujairika kana kwakakwira kupfuura zvinotarisirwa, panogona kunge paine nyaya nechikamu kana masolder majoini.Kunzwisisa iyo inotarisirwa voltage panzvimbo dzekuedzwa kunogona kubatsira mukuongororwa kwedunhu.

Imwe nzira yekuongorora zvikamu ndeye kuburikidza ne nodal analysis.Iyi nzira inosanganisira kuisa voltage kune zvakasarudzwa asi usingabatisi dunhu rose uye kuyera mhinduro dzevoltage (V-response).Ziva node dzese uye sarudza referensi yakabatana kune zvakakosha zvikamu kana masimba emagetsi.Shandisa Kirchhoff's Current Law (KCL) kuverengera zvisingazivikanwe node voltages (variables) uye tarisa kana aya ma values achienderana neanotarisirwa.Kana paine nyaya dzinocherechedzwa pane imwe node, inoratidza kukanganisa pane iyo node.

3-5.Kuedza Integrated Circuits

Kuyedza masekete akabatanidzwa anogona kuve basa rakakura nekuda kwekuoma kwawo.Heino mimwe miedzo inogona kuitwa:

- Ziva zvese zvinomaka uye edza iyo IC uchishandisa logic analyzer kana oscilloscope.

- Tarisa kana iyo IC yakanangana nemazvo.

- Ita shuwa kuti ese majoini ekutengesa akabatana neIC ari mumamiriro ekushanda akanaka.

- Ongorora mamiriro ekupisa chero kunyura kana mapedhi ekupisa akabatana neIC kuti ave nechokwadi chekupisa kwakakodzera.

3-6.Kuedza Simba rekupa

Kuti ugadzirise nyaya dzemagetsi emagetsi, zvinodikanwa kuyera njanji voltages.Iko kuverenga pane voltmeter kunogona kuratidza kupinza uye kuburitsa kukosha kwezvikamu.Kuchinja kwemagetsi kunogona kuratidza matambudziko anogona kuitika edunhu.Semuenzaniso, kuverenga kwe0V pane njanji kunogona kuratidza dunhu pfupi mumagetsi emagetsi, zvichitungamira kune chikamu chekupisa.Nekuita bvunzo dzekuvimbika kwesimba uye kuenzanisa hunhu hunotarisirwa kune zviyero chaizvo, dambudziko remagetsi rinogona kutsaurwa.

3-7.Kuziva Circuit Hotspots

Kana kukanganisa kwekuona kusingakwanisi kuwanikwa, kuongorora kwemuviri kuburikidza nejekiseni remagetsi kunogona kushandiswa kuongorora dunhu.Kubatana kwakashata kunogona kuunza kupisa, kunogona kunzwika nekuisa ruoko pabhodhi redunhu.Imwe sarudzo ndeye kushandisa thermal imaging kamera, iyo inowanzofarirwa kune yakaderera-voltage maseketi.Kuchengetedza kunofanirwa kunofanirwa kutorwa kudzivirira njodzi dzemagetsi.

Imwe nzira ndeyekuona kuti unoshandisa ruoko rumwe chete pakuyedza.Kana panopisa paonekwa, inoda kutonhodzerwa pasi, uyezve mapoinzi ese ekubatanidza anofanirwa kutariswa kuti paonekwe kuti nyaya iri papi.

3-8.Kugadzirisa matambudziko neSignal Probing Techniques

Kuti ushandise iyi tekinoroji, zvakakosha kuve nekunzwisisa kwezvinotarisirwa kukosha uye mafungu esaisai panzvimbo dzebvunzo.Kuyedzwa kwemagetsi kunogona kuitwa panzvimbo dzakasiyana uchishandisa multimeter, oscilloscope, kana chero waveform yekubata mudziyo.Kuongorora mhedzisiro kunogona kubatsira mukusiyanisa zvikanganiso.

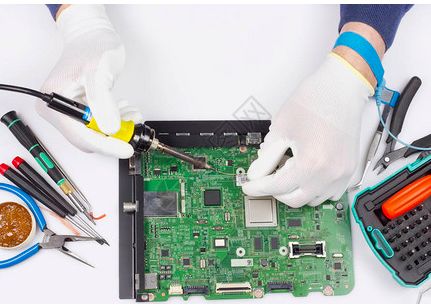

4. Zvishandiso Zvinodiwa Pakugadzirisa PCB

Usati wagadzirisa, zvinokosha kuunganidza maturusi anodiwa pabasa racho, sezvinotaurwa chirevo chokuti, 'Banga rakagomara haritemi huni.'

● Tafura yekushanda yakashongedzerwa neESD grounding, zvigadziko zvemagetsi, uye chiedza chakakosha.

● Kuti udzikise kupisa kwemhepo, infrared heaters kana preheaters inogona kudiwa kuti itange kupisa bhodhi redunhu.

● Chigadziro chekuchera chakanyatsodiwa chinodiwa pakupinza uye kuzarura gomba panguva yekugadzirisa.Iyi sisitimu inobvumira kutonga pamusoro pehupamhi nekudzika kweiyo slots.

● Simbi yakanaka yakanyungudutswa inodiwa kuti isimbiswe kuti ivimbise majoini akakodzera.

● Mukuwedzera, electroplating inogonawo kudiwa.

● Kana iyo solder mask layer yakakanganiswa, inoda kugadziriswa.Mumamiriro ezvinhu akadaro, epoxy resin layer inodiwa.

5. Kuchengetedza Kuchengetedza panguva yePCB Repair

Zvakakosha kutora matanho ekudzivirira kudzivirira njodzi dzekuchengetedza panguva yekugadzirisa.

● Midziyo Yekudzivirira: Paunenge uchibata nekupisa kwepamusoro kana simba rakakwirira, kupfeka midziyo yekudzivirira inofanirwa.Magirazi ekuchengetedza uye magurovhosi anofanirwa kupfekwa panguva yekushambadzira uye kuchera maitiro, kudzivirira kubva kune inogona kuve njodzi yemakemikari.

Kupfeka magirovhosi paunenge uchigadzira maPCB.

● Electrostatic Discharge (ESD): Kudzivirira kuvhunduka kwemagetsi kunokonzerwa neESD, iva nechokwadi chekusunungura simba remagetsi uye kubvisa chero magetsi asara.Iwe unogona zvakare kupfeka mabhandi epasi kana kushandisa anti-static mats kuti uwedzere kudzikisira njodzi yeESD.

6. Nzira yekugadzirisa sei PCB?

Kukanganisa kwakajairika muPCB kunowanzo sanganisira kukanganisa mumateki, zvikamu, uye solder pads.

6-1.Kugadzirisa Maronda Akakuvadzwa

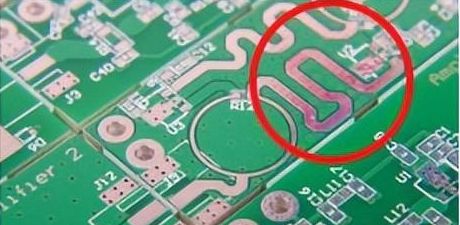

Kugadzirisa zvakatyoka kana kukuvadzwa zvisaririra paPCB, shandisa chinhu chakapinza kuburitsa pachena nzvimbo yepakutanga trace uye bvisa solder mask.Chenesa nzvimbo yemhangura ne solvent kubvisa chero tsvina, zvichibatsira kuwana zviri nani kuenderera kwemagetsi.

Neimwe nzira, unogona solder jumper waya kugadzirisa maronda.Ita shuwa kuti dhayamita yewaya inoenderana nehupamhi hwekutsvagisa kune kwayo conductivity.

6-2.Kutsiva Zvakaipa Zvikamu

Kutsiva zvikamu zvakakanganisika

Kuti ubvise zvikamu zvakakanganisika kana kuti solder yakawandisa kubva kune solder joints, zvakakosha kunyungudutsa solder, asi kuchenjerera kunofanira kutorwa kudzivisa kuunza kushushikana kwekushisa panzvimbo yakapoteredza.Kutevera matanho ari pasi apa kutsiva zvikamu mudunhu:

● Pisa majoini emasolder nekukurumidza uchishandisa iron inodhaka kana kuti desoldering tool.

● Kana solder yanyungudutswa, shandisa pombi inoparadza kubvisa mvura.

● Mushure mokubvisa zvose zvakabatanidzwa, chikamu chichabviswa.

● Zvadaro, unganidza chinhu chitsva uye tengesa panzvimbo.

● Cheka kureba kwakawandisa kwechikamu chinotungamira uchishandisa waya dzinocheka.

● Ita shuwa kuti materminal akabatana maererano neinodiwa polarity.

6-3.Kugadzirisa Yakakuvadzwa Solder Pads

Nekufamba kwenguva, solder pads paPCB inogona kusimudza, kukanganisa, kana kupwanya.Hedzino nzira dzekugadzirisa dzakakuvadzwa solder pads:

Akasimudzwa Solder Pads: Geza nzvimbo yacho nesolvent uchishandisa donje swab.Kuti usunge padhi panzvimbo, isa conductive epoxy resin pane solder pad uye woitsikirira pasi, uchibvumira epoxy resin kurapa isati yaenderera mberi nekutengesa.

Yakakuvadzwa kana Yakasvibiswa Solder Pads: Bvisa kana cheka pakakuvadzwa solder pad, uchifumura yakabatana trace nekukwenya kubva solder mask yakatenderedza padhi.Geza nzvimbo yacho nesolvent uchishandisa cotton swab.Pane itsva solder pad (yakabatana kune trace), isa dhizaini ye conductive epoxy resin uye chengetedza panzvimbo.Tevere, wedzera epoxy resin pakati peiyo trace uye solder pad.Iporese usati waenderera mberi nekugadzirisa.

Shenzhen ANKE PCB Co., LTD

2023-7-20

Nguva yekutumira: Jul-21-2023